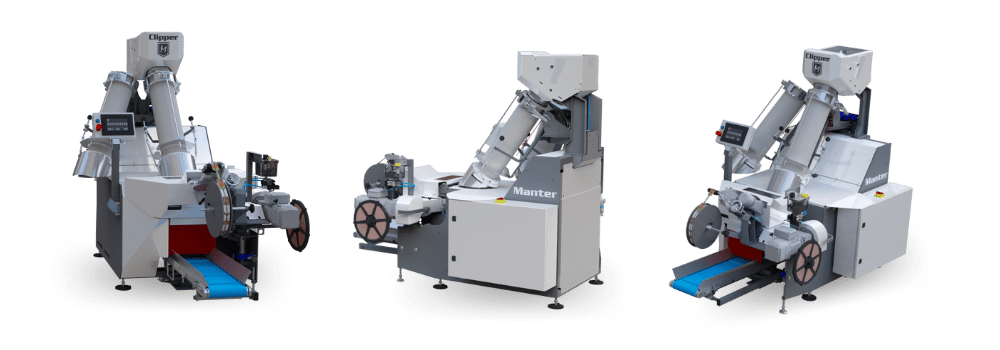

The Clipper has been built by Manter since the 1990s. It has been improved over the years and recently the third version was released: a Clipper M3. This is a response to the demand from the market in which the requirements in terms of quality, speed and appearance have become ever higher. Thus, the main development requirements were: a high-quality machine with a high degree of user-friendliness and optimum capacity. To achieve this, almost the entire Clipper M2 has been revised and improved in the 3rd generation of the Clipper.

The following has been improved:

- The frame on the infeed side has been shortened by about 180 mm, allowing the placement of two Clippers under a weigher with dual discharge system.

- The pivot point in the frame for access to the Clip head has been moved to under the Clip head, as opposed to beside the frame as it was on the Clipper M2. Relocation ensures a smaller required footprint of the entire machine and good accessibility to the Clip Head.

- The caps around the frame have received a re-design for a more modern look.

The intermediate buckets have been completely redesigned. Whereas previously these had rotating valves where the product was collected, this has now become a slide in a round hopper. This reduces the chance of clogging and for many types of product will increase capacity. - The aforementioned Clip head is fitted with automatic oil lubrication as standard. During operation, oil is automatically added for the moving parts inside the Clip head to reduce wear and maintenance intervals.

- The Clipper M3 features a new intuitive touchscreen operation. The software behind this runs on an updated PLC platform.

The following were already improved:

Some of the developments intended for the Clipper M3 had already been implemented on the Clipper M2:

- The filler tubes are made of PP instead of PVC. PP is more impact-resistant than PVC, reducing the risk of breakage if the tube is dropped.

- Tubes still change on the M3 via a pivot point, ensuring easy access to the tube for tube net replacement.

- Also in the Clipper M3, the support belt has become a fixed part of the machine. This has reduced the construction size of the belt, so more space is available for a discharge belt after the Clipper and a broom fits more easily under the belt.

- The Labeler has been further redesigned for easier label feeding and adjustment. For label printing, there is again a choice between a tabletop printer or a Smartdate printer from Markem, both of which are mounted in a housing. A tray is provided in the frame for the label-dependent guide rolls.

3rd and only generation

With this complete redevelopment of the Clipper to the 3rd generation, Manter has managed to refine its Clipper even further. The first Clippers M3 are now in production. With the arrival of the latest version, the Clipper M2 is therefore no longer available.