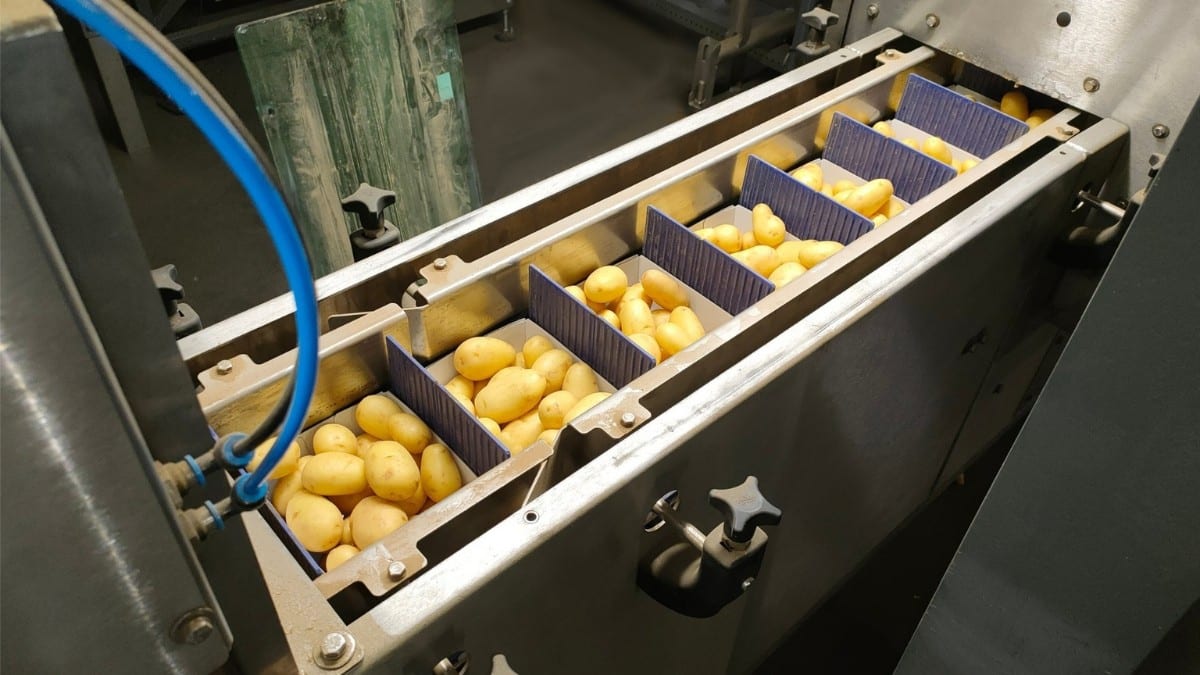

This year we introduced a new version of our punnet filler. We optimized several aspects of the machine based on the feedback from our customers. The main improvements we’ve made are greater accuracy, which means less spillage and optimal tray filling. In addition, we managed to keep the capacity at 40 punnets per minute. All these optimizations have been implemented while maintaining the product-friendliness that Manter is known for.

Customer case

Last April we installed our new punnet filler at a customer in Germany. The punnet filler has been specially developed to be able to fill two different sizes of punnets very accurately. In this particular case, we have devoted extra time and attention to optimizing efficiency for our customer, both in filling the punnets and in machine changeover time.

High degree of filling

The punnets are filled “long-side-leading” for optimum machine and product flow efficiency. In order to make sure that a punnet is filled to the edge but to avoid that product is spilled, punnets are shaken back and forth in a shaking station after filling. The punnets then move over a vibrating plate, which makes sure the potatoes are compactly positioned in the punnet. During this proces side guides on all sides of the punnet prevent product of falling out. The pushing station gently pushes the full punnets off with variable speeds, while the return movement is at full speed. Finally, the singulation station singulates the punnets by means of a retracting cylinder. The punnets are ready for the flow-wrapper!

Minimal changeover times

In addition to the optimal efficiency of filling the punnets, the changeover time has also been reduced to a minimum. In collaboration with our supplier for denesting systems, a system has been developed in which it is possible to switch quickly and easily between the two types of punnets. Where previously ±20 minutes of modifications were needed to change punnets, one now simply slides a filling plate into the machine so that it is ready to run within a minute.

Michiel Eilander

sales@manter.com

+31 591 626 300

Feel free to contact us for personal advice!