Low roof? No problem!

When working on a layout, space is often a limiting factor. You need room to maneuver a forklift, and sometimes the walls or ceiling can feel like they’re closing in on you. Don’t forget about the mechanic who occasionally needs to check the machines. We have to work around all these limitations, but luckily, we have some tools to help.

Solving height restrictions

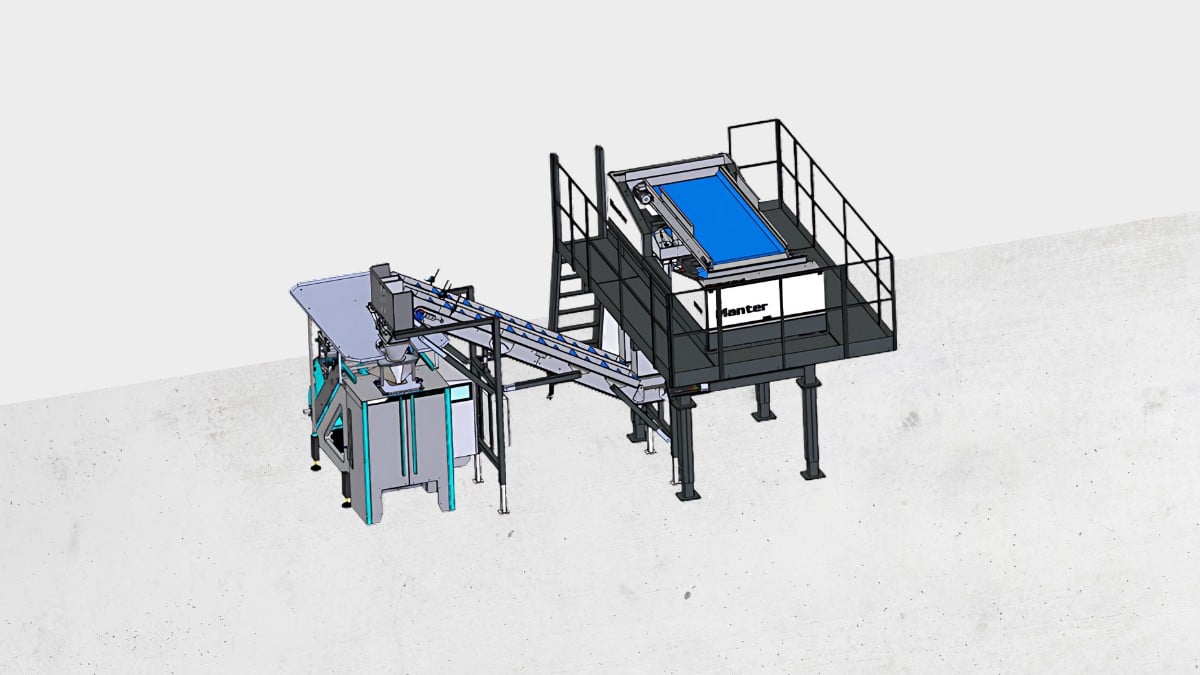

For example, consider a vertical bagger in a building with a low ceiling. The weigher with the infeed belt fits easily, but the vertical bagger, which is quite tall, needs to fit under the weigher. It doesn’t! Fortunately, there is a solution: a belt with dedicated slots where each portion sits and travels upward. This is called a Compartment Belt, and it makes it possible to get the product up to your desired height

Maintaining speed and accessibility

Adding additional belts or machines to your setup can limit the speed, and we want to prevent this. That’s why a Compartment Belt consists of two belts and a bucket at the end. The belts run alternately, ensuring that there is always a portion ready for your bagger. An additional advantage is that you create space around the bagger, making everything easily accessible.

Expert assistance for optimal layouts

With these complex setups, our dealers can provide excellent assistance. They have the experience and knowledge to configure your layout efficiently, ensuring that all machines work together seamlessly within the available space. Whether you’re dealing with height restrictions, limited floor space, or accessibility concerns, our solutions help maximize efficiency without compromising performance.