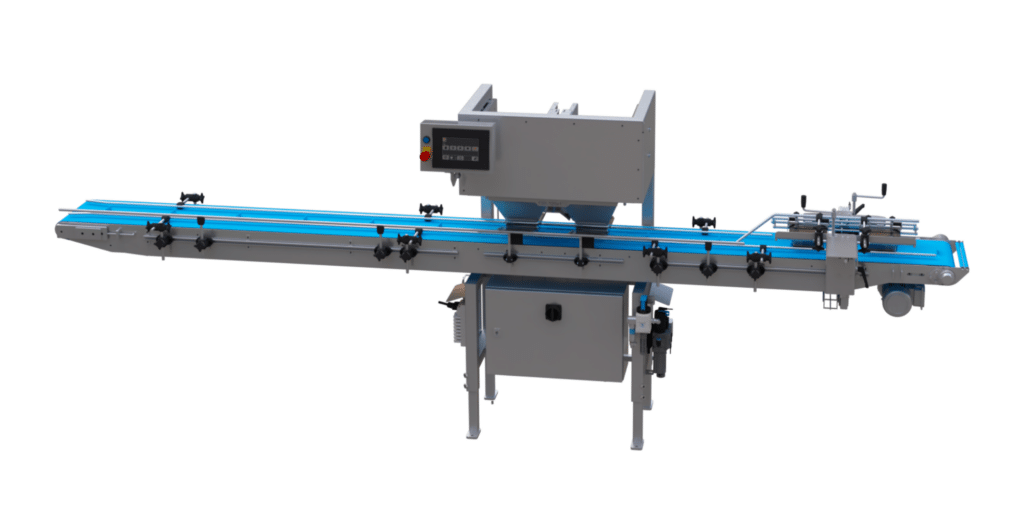

Manter, a specialist in weighing and packaging solutions, expands its portfolio with the launch of the brand-new Punnet Filler. This automatic packaging machine is highly user-friendly and responds to the growing market demand, particularly the increasing need for sustainable punnet packaging. As the name suggests, the latest Punnet Filler is specifically designed for the efficient packaging of punnets. Additionally, the machine can be adapted for use with clamshells. Earlier this month, the latest M14i D was also launched.

Punnet Filler

Manter’s latest Punnet Filler sets a new standard in automatic packaging filling. This automated machine fills and transports two trays simultaneously, achieving a speed of 44 trays per minute. This makes the Punnet Filler particularly suitable for companies looking to boost production efficiency without compromising on quality. Additionally, the drop height of the product is minimized as the filling station moves downward during the filling process, ensuring the product remains in optimal condition.

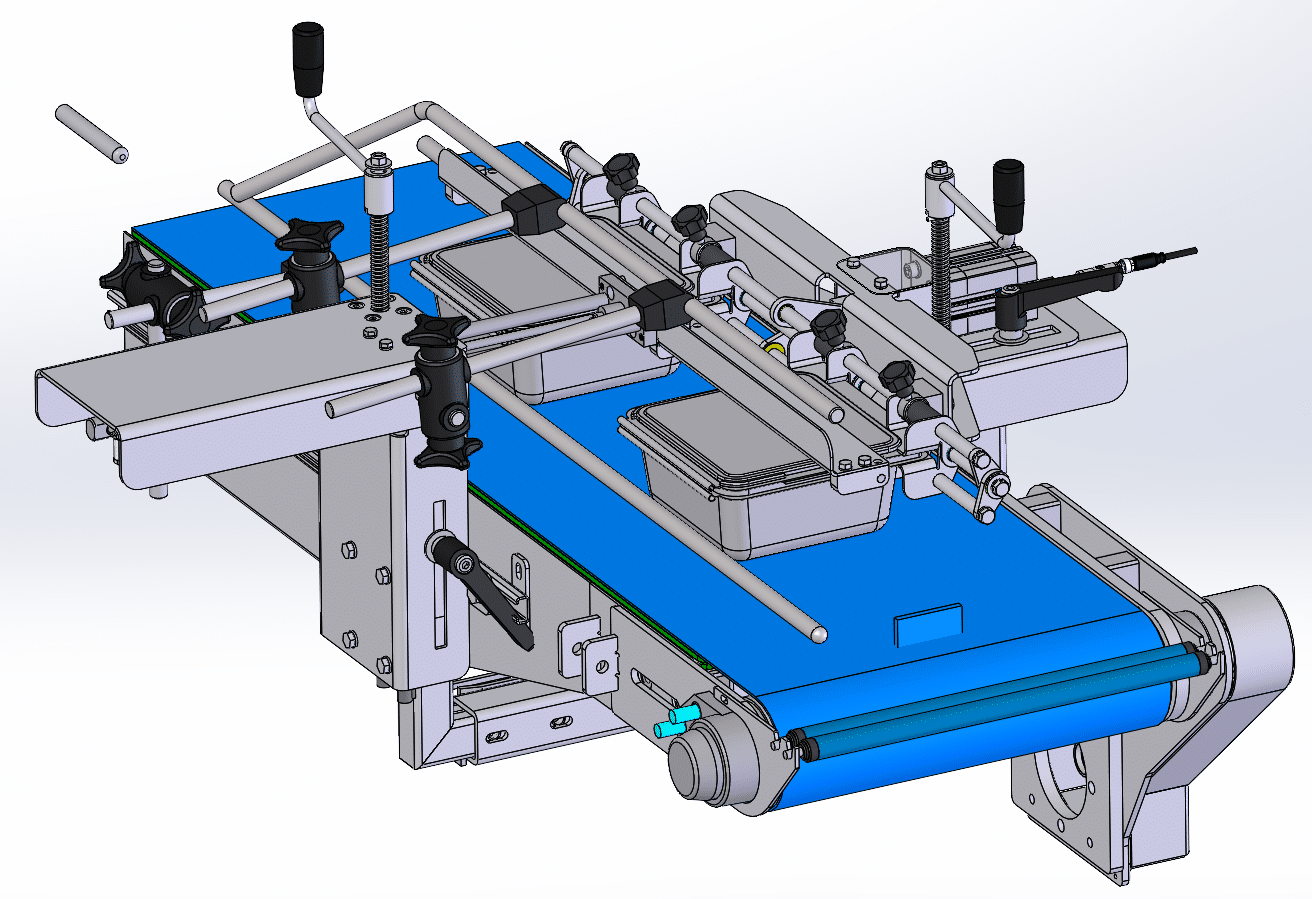

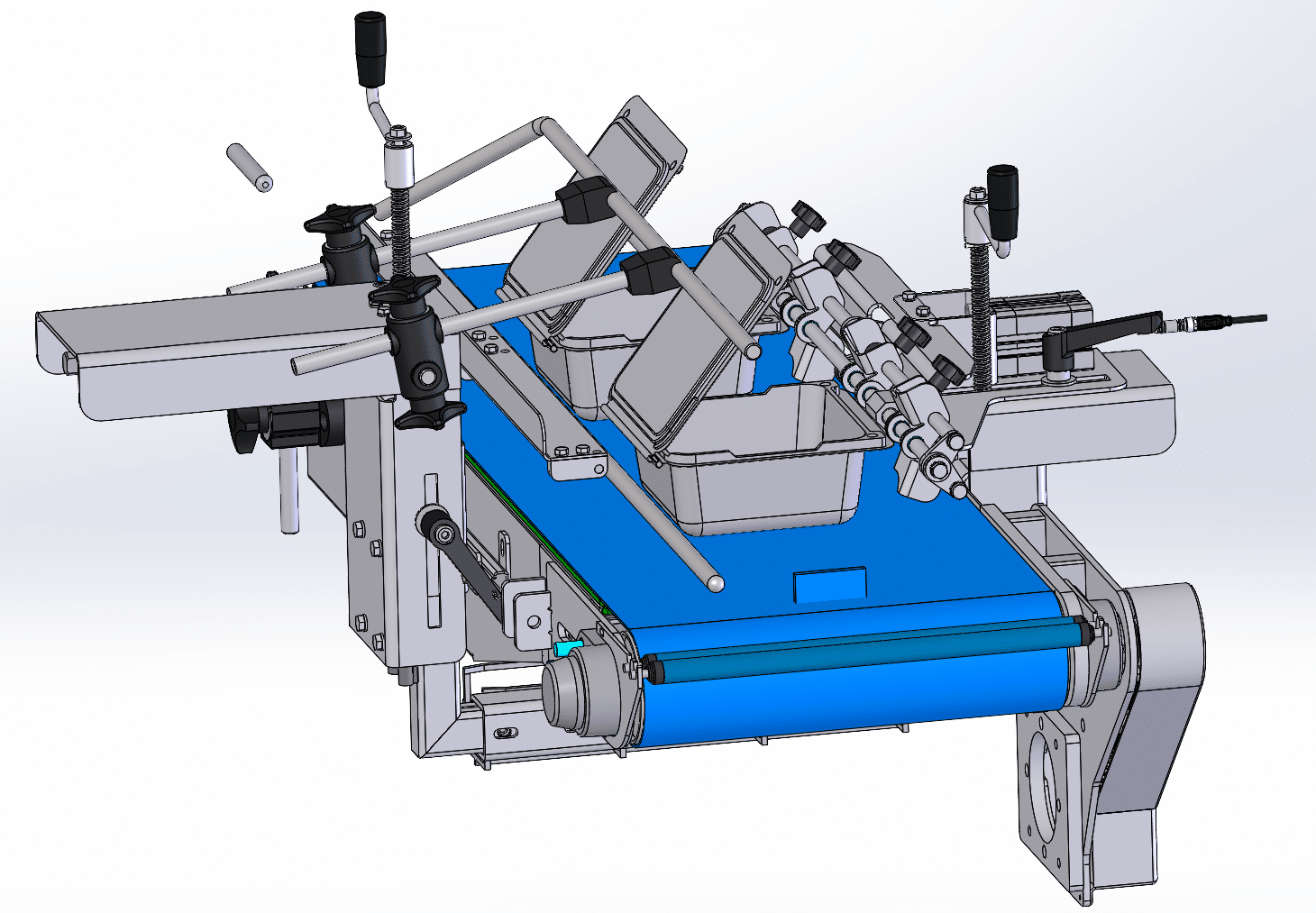

The machine can be configured for both (paper) punnets and (plastic) clamshells. Depending on the selected application, a clamshell closing unit may be mounted on the machine. When the Punnet Filler is equipped with a clamshell closing unit, this unit is adjustable and can be easily adapted to various sizes of punnets or clamshells. This applies to both the front-closure and corner-closure designs of clamshells. To accommodate clamshells of any size, an ingenious roller system is used, which can be easily adjusted to fit any clamshell format, minimizing changeover times.

Roller System for Closing Clamshells

The trays can be placed manually on the conveyor belt, but the machine can also be easily combined with an automatic destacker. This allows the packaging process to be fully automated. Thanks to the two-plane guidance system, the trays always align properly on the belt. Additionally, the machine is easy to operate via a touchscreen and is more maintenance-friendly due to a careful selection of materials. Mechanical engineer Albert Veldhuis concludes: “The various improvements were made by listening to feedback from our customers, with the goal of further optimizing ease of use.”

Punnet Filler +

In addition to the Punnet Filler, Manter is also launching a “+” version. The difference between these two models lies in the type of conveyor belt used to transport the trays forward. The standard version uses a belt with flights, which requires a fixed spacing for trays supply. The Punnet Filler+ features a flat belt, where “stoppers” ensure the trays stay in the correct position for filling or closing. This enables the Punnet Filler+ to handle an irregular supply of trays.

Veldhuis explains: “These machines are fully constructed in stainless steel and have an IP rating of 65, making them suitable for use in food production environments.” Additionally, both machines seamlessly integrate with a IMA Record Flow Wrapper or a Top Sealer, which are also part of Manter’s product portfolio.

About Manter

Manter is a leading provider of high-quality weighing and packaging solutions. With decades of experience in the industry, Manter delivers innovative machines designed to meet the specific needs of customers worldwide. Its focus on quality, flexibility, and user-friendliness makes Manter a trusted partner in the packaging industry.

Machine reveal

At Fruit Logistica 2025, the Punnet Filler will be showcased for the first time at the Manter stand. This is an exclusive opportunity for visitors to be among the first to see the new packaging machine unveiled at the leading international trade fair for the fruit and vegetable sector.

Location of Manter at Fruit Logistica 2025: Hall 2.1, Stand C-40.