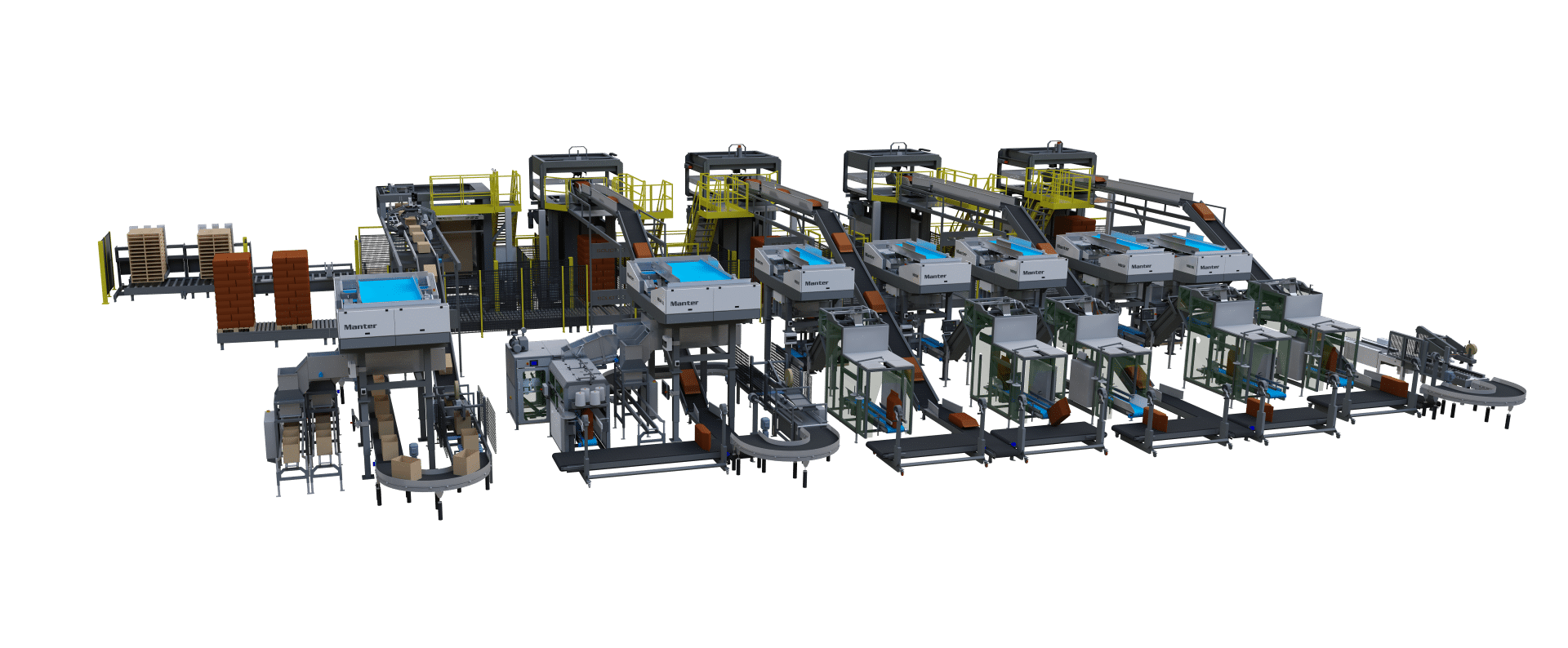

Manter provides an advanced IPC and software system that connects all Manter weighing, packaging, and palletizing machines. This enables customers to centrally manage their entire production line, with the ability to remotely monitor and control operations from a single, clear interface. Line Control communicates seamlessly with all Manter machines and allows users to control settings, performance, and processes of the complete packaging line from one central location.

Three key functions

Line Control contains three key functions: start/stop control of the entire line, automatic preset switching for each machine, and clear error display with logging. This makes changing pack sizes fast and effortless. For example, when switching from 10 to 25 kg bags, Line Control automatically adjusts all connected machines to the correct presets. After loading the new bags and confirming the recipe, the complete line can be restarted with a single command.

Increasing efficiency

Line Control streamlines Manter’s packing line, boosting efficiency.

Short changeover times

All presets can be changed at once and Manter’s fully automatic machines will adjust accordingly.

Insight in performance

Line Control reduces operator failure significantly and enables the user to make data-driven decisions to optimise production.

Reducing labor costs

With Line Control the management and control of the packaging line will become less labour intensive.