In September we had the pleasure of visiting Poppe Landbouw, a beautiful family business with a passion for growing and retailing organic crops. What makes Poppe Landbouw so special is that they carry out several processes in the supply chain: they grow crops and then process, package and sell the products in-house. Poppe Landbouw successfully carries out the packaging process with a Manter weighing and packaging line.

About Poppe landbouw

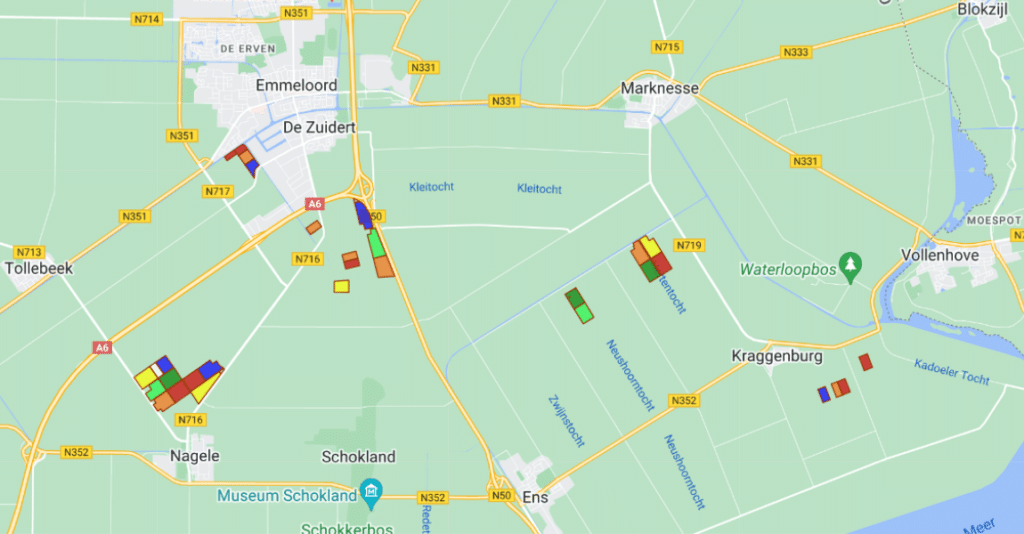

Poppe Landbouw has been located in Nagele since 1958, and has been fully organically certified since 2002. Brothers Joos and Marien Poppe run the company together with a team of 11 employees. On 250 hectares of land they grow a varied range of crops, including carrots, seed potatoes, chicory roots, red and yellow onions, shallots, alfalfa and grass-clover, according to a carefully planned crop rotation of one in six. After harvesting, they store the products on their own premises as much as possible. The onions are then processed, sorted, packaged and prepared for delivery by Poppe Landbouw. The unique aspect of the company is that they not only grow, but also manage the processing and packaging process in-house, unlike many other farmers who limit themselves to growing and have their products packaged elsewhere. We are pleased that Poppe Landbouw has chosen Manter as a partner and that our machines contribute to making this process possible.

The Manter line

During our visit, the packaging process was in full swing, with the onions being packed at a rapid pace using the M16i V weigher in combination with two Clippers M2 packaging machines. “The line runs like a charm,” said Marien Poppe with satisfaction. The onions were packed in mesh bags of 250 to 1000 grams, intended for delivery to Albert Heijn, the largest supermarket chain in the Netherlands. At Manter, not only the efficiency of packaging speed and changeover times is central, but also the condition of the product after the packaging process. The M16i V weigher is specially designed for the accurate weighing of smaller products, where delicate handling is essential to maintain the optimal condition of the onions. This treatment does not affect the speed of the machine, which can process as many as 80 deposits per minute. Poppe therefore “consciously chose Manter”.

Double capacity

By connecting two clipper packaging machines to their weigher, Poppe can pack at a speed of 200%. This seems like a logical calculation, but it is not self-evident. The weigher must also be able to handle this capacity and the connected Manter weigher can do that. This integrated line offers numerous advantages and possibilities, to which we are fully committed. Poppe indicated that he was very satisfied with our machines and we are of course proud of that.

We would like to thank Poppe Landbouw for their hospitality during our visit to their company and look forward to continuing our fruitful cooperation.

For more information, please contact:

Manter International:

sophie.wehkamp@manter.com